We produce

Grease separators

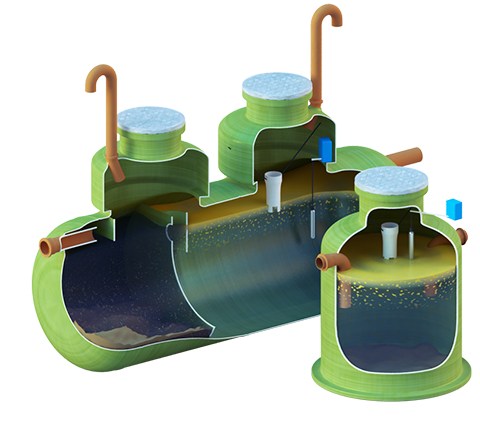

Grease separators are used for treating sewage from grease products and vegetable oil before entering the sewer system or the system of subsequent purification.

The principle of function of grease separators is based on the difference between specific densities of grease products and water (in the case of standage, particles of fats and oils rise to the surface).

All grease separators are CE-certified and manufactured in accordance with EN 1825.

- Cafes, bars and restaurants;

- Hotels and leisure centres;

- Food bases, warehouses and shops;

Efficiency

Owing to the special system of inner overfalls, our grease separators ensure cleaning up in terms of oil of up to 50 mg/l. If desired, we will increase the level of cleaning up by 5 mg/l.

Economical efficiency

We provide special grease separators/ wells for low-power system.

Choise

Follow the agreed guidelines to select a grease separator independently.

Control

Various control systems are available for prompt maintenance — control of the sludge, oil, and oil products level.

How it works

In standard versions, our grease separators have two chambers. In the first chamber, hard particles are neutralised by desilting. In the second chamber, oil and grease particles are fusioned with the following floating-up of emulsified fats.

Full service

We provide full service — calculation, design, manufacture, packaging, delivery, installation supervision, starting-up and adjustment, as well as maintenance. Turnkey solutions.